Personal Protective Equipment (PPE) plays a crucial role in safeguarding workers from workplace hazards, minimizing risks, and ensuring their well-being. From hard hats to respirators, PPE serves as a frontline defense against potential injuries and illnesses, enabling individuals to perform their duties with confidence and protection.

In this comprehensive guide, we will delve into the world of PPE, exploring its types, standards, hazard assessment, training, maintenance, and best practices. We will also showcase innovative technologies and industry trends that are shaping the future of workplace safety.

Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) plays a crucial role in safeguarding workers from potential hazards and injuries in various industries. It is designed to protect the wearer’s body, eyes, ears, respiratory system, hands, feet, and skin from exposure to hazardous substances, machinery, or environmental factors.

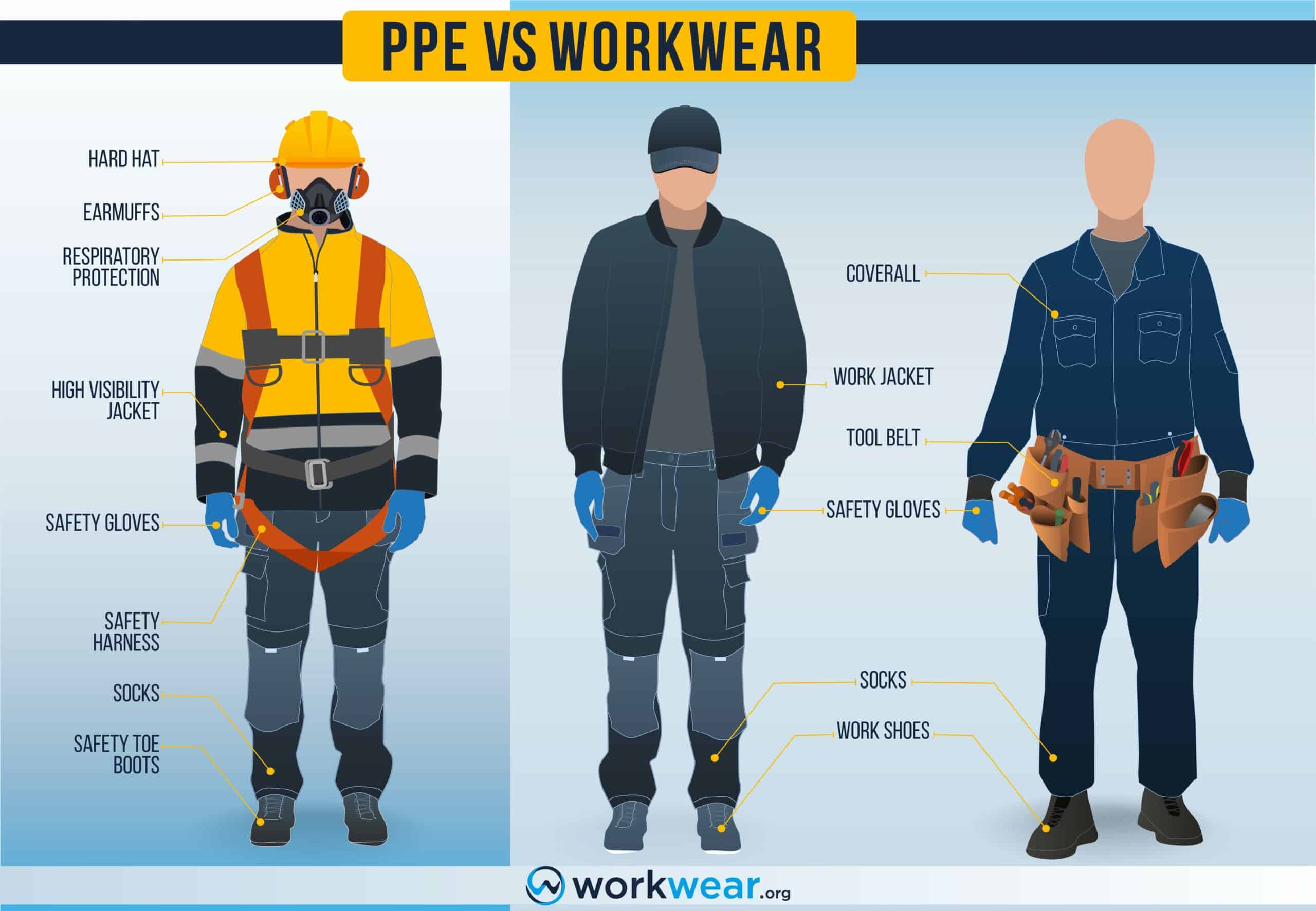

Types of PPE

- Head protection: Hard hats, bump caps

- Eye protection: Safety glasses, goggles

- Hearing protection: Earplugs, ear muffs

- Respiratory protection: Respirators, face masks

- Hand protection: Gloves

- Foot protection: Safety shoes, boots

- Body protection: Coveralls, aprons

Regulations and Standards

The use of PPE is regulated by various organizations, including:

- Occupational Safety and Health Administration (OSHA)

- American National Standards Institute (ANSI)

- European Union (EU)

These regulations and standards ensure that PPE meets specific safety requirements and is appropriate for the intended use.

Industries Where PPE is Essential

- Construction

- Manufacturing

- Healthcare

- Transportation

In these industries, workers are exposed to various hazards that can be mitigated by the use of appropriate PPE.

PPE Standards and Regulations

PPE standards and regulations are crucial for ensuring the safety of individuals in workplaces where hazards are present. These standards provide guidelines for the selection, use, and maintenance of PPE to protect workers from potential risks.

Role of Organizations

Organizations like the Occupational Safety and Health Administration (OSHA) and the American National Standards Institute (ANSI) play a vital role in establishing PPE standards. OSHA is the primary federal agency responsible for ensuring workplace safety and health, while ANSI is a private, non-profit organization that develops consensus standards for various industries.

OSHA sets mandatory PPE standards that employers must follow to protect their employees from workplace hazards. These standards cover a wide range of PPE, including respirators, gloves, eye protection, and protective clothing. ANSI develops voluntary consensus standards that provide detailed specifications for the design, performance, and testing of PPE. These standards are widely recognized and used by manufacturers, employers, and safety professionals to ensure the quality and effectiveness of PPE.

Importance of Adherence

Adhering to PPE standards is essential for workplace safety. By following these standards, employers can provide their employees with the necessary protection against potential hazards. Proper selection, use, and maintenance of PPE can significantly reduce the risk of injuries and illnesses, ensuring a safer work environment.

Failure to comply with PPE standards can have serious consequences. Employers who do not provide adequate PPE or fail to ensure proper use and maintenance can be held liable for any resulting injuries or illnesses. Workers who do not use PPE properly or who use defective PPE are also at increased risk of harm.

By understanding and adhering to PPE standards and regulations, employers and employees can work together to create a safer and healthier workplace.

PPE Hazard Assessment

Conducting a thorough PPE hazard assessment is crucial to ensure the selection and use of appropriate personal protective equipment. This process involves identifying potential hazards, evaluating their severity, and determining the likelihood of exposure.

Further details about Polizei is accessible to provide you additional insights.

Factors to Consider

- Nature of the hazard: Chemical, physical, biological, etc.

- Severity of the hazard: Can it cause injury or illness?

- Likelihood of exposure: How often and for how long?

Selecting Appropriate PPE

Based on the hazard assessment, select PPE that provides adequate protection. Consider:

- Type of PPE: Respirators, gloves, eye protection, etc.

- Level of protection: Disposable vs. reusable, high-visibility vs. standard

- Fit and comfort: Ensure proper fit for effectiveness and user acceptance

Developing and Implementing a PPE Program

Establish a comprehensive PPE program that includes:

- Policies and procedures for PPE use

- Training employees on PPE selection, use, and maintenance

- Maintaining and inspecting PPE to ensure its effectiveness

- Enforcing PPE use to protect employees

Importance of Regular PPE Inspections and Maintenance

Regular PPE inspections and maintenance are essential for ensuring its effectiveness. This includes:

- Visual inspections: Check for damage, wear, or contamination

- Functional testing: Ensure PPE meets performance standards

- Decontamination and cleaning: Remove contaminants to prevent exposure

Proper Disposal of PPE

Dispose of PPE properly to prevent contamination and environmental hazards.

- Contaminated PPE: Dispose of according to hazardous waste regulations

- Non-contaminated PPE: Dispose of in regular trash or recycle if possible

Explain the importance of PPE training and education for employees in preventing workplace injuries and illnesses.

PPE training and education are crucial for employees to understand the proper use, maintenance, and limitations of PPE. By providing employees with comprehensive training, employers can equip them with the knowledge and skills necessary to protect themselves from workplace hazards and reduce the risk of injuries and illnesses.

Effective PPE training programs empower employees to make informed decisions regarding their safety, fostering a culture of safety awareness and responsibility within the workplace.

Methods of PPE Training and Education

There are several methods of PPE training and education, each with its own advantages and suitability for different workplace settings and learning styles.

Check Nicole Kidman Practical Magic to inspect complete evaluations and testimonials from users.

- On-the-job training: This method involves hands-on instruction and guidance from a supervisor or experienced colleague while performing work tasks. It allows employees to learn in a real-world setting and practice using PPE under supervision.

- Classroom training: This method involves structured presentations, discussions, and demonstrations conducted in a classroom setting. It provides a comprehensive overview of PPE, its uses, and limitations, and allows for interactive learning and Q&A sessions.

- Online training: This method utilizes online platforms and modules to deliver training materials. It offers flexibility and convenience for employees to learn at their own pace and on their own time. Online training can include interactive simulations and quizzes to enhance engagement and knowledge retention.

- Computer-based training (CBT): This method uses computer software and simulations to provide interactive and engaging training experiences. CBT allows employees to learn through scenarios and simulations, providing a realistic and immersive learning environment.

PPE Maintenance and Inspection

PPE maintenance and inspection are critical components of an effective PPE program. Regular maintenance and inspection ensure that PPE is in good working condition and provides the intended level of protection.

Importance of Regular PPE Maintenance and Inspection

Regular PPE maintenance and inspection help:

– Ensure PPE is functioning properly and provides the intended level of protection.

– Identify and address any damage or defects that could compromise PPE’s effectiveness.

– Prolong the lifespan of PPE, saving costs on replacements.

– Comply with regulatory requirements and industry best practices.

Types of PPE Maintenance and Inspection Procedures

PPE maintenance and inspection procedures vary depending on the type of PPE. Common procedures include:

– Visual inspection: A thorough visual examination to identify any visible damage, wear, or defects.

– Functional testing: Tests to ensure that PPE components, such as respirators or fall protection systems, are operating correctly.

– Quantitative testing: Advanced testing methods to measure the performance of PPE against specific standards.

Establishing a PPE Maintenance and Inspection Program

To establish a comprehensive PPE maintenance and inspection program:

– Define the scope and frequency of maintenance and inspection activities.

– Assign responsibilities for conducting inspections and maintenance.

– Develop clear procedures and documentation for all maintenance and inspection tasks.

– Train personnel on the proper use and care of PPE.

– Implement a system for tracking and recording inspection and maintenance activities.

Benefits of Using PPE Maintenance and Inspection Software

PPE maintenance and inspection software can streamline and enhance the process by:

– Automating inspection and maintenance schedules.

– Tracking the history of PPE inspections and maintenance.

– Generating reports for compliance audits.

– Providing reminders and alerts for upcoming inspections and maintenance tasks.

Steps Involved in Conducting a PPE Inspection

Conducting a PPE inspection typically involves the following steps:

1. Gather the necessary PPE and inspection tools.

2. Perform a visual inspection for any visible damage or defects.

3. Conduct functional testing, if applicable.

4. Document the inspection findings.

5. Take corrective actions to address any identified issues.

PPE Maintenance and Inspection Checklist

A comprehensive PPE maintenance and inspection checklist should include the following items:

– PPE type

– Inspection date

– Inspector’s name

– Visual inspection findings

– Functional testing results

– Corrective actions taken

– Signature of inspector

Table of PPE Maintenance and Inspection Requirements

The following table summarizes the maintenance and inspection requirements for different types of PPE:

| PPE Type | Maintenance and Inspection Requirements |

|—|—|

| Respirators | Visual inspection, functional testing, quantitative testing (as required) |

| Gloves | Visual inspection, functional testing (if applicable) |

| Eye protection | Visual inspection, functional testing (if applicable) |

| Hearing protection | Visual inspection, functional testing (if applicable) |

| Fall protection | Visual inspection, functional testing, quantitative testing (as required) |

Flowchart Outlining the PPE Maintenance and Inspection Process

[Flowchart outlining the PPE maintenance and inspection process]

Proper Storage and Disposal of PPE

Proper storage and disposal of PPE are essential for maintaining its effectiveness and safety:

– Store PPE in a clean, dry, and well-ventilated area.

– Inspect PPE before each use and after cleaning.

– Dispose of damaged or expired PPE according to manufacturer’s instructions and applicable regulations.

Training and Certification of Personnel

Personnel responsible for PPE maintenance and inspection should be trained and certified to ensure they have the necessary knowledge and skills. Training should cover topics such as:

– PPE types and their applications

– PPE maintenance and inspection procedures

– Recordkeeping and documentation

– Compliance with regulatory requirements

PPE Storage and Disposal

Proper storage and disposal of PPE are crucial to maintain its effectiveness and prevent workplace hazards. Neglecting these aspects can compromise the integrity of PPE, reducing its protective capabilities and potentially leading to injuries or illnesses.

Proper Storage of PPE

- Store PPE in a clean, dry, and well-ventilated area.

- Keep PPE away from direct sunlight, heat sources, and corrosive chemicals.

- Inspect PPE regularly for signs of damage or wear and replace it as necessary.

- Store different types of PPE separately to prevent contamination or damage.

Proper Disposal of PPE

- Dispose of single-use PPE (e.g., disposable gloves, masks) in designated waste containers.

- For reusable PPE, follow manufacturer’s instructions for proper cleaning and disinfection.

- Consider recycling or donating reusable PPE that is still in good condition.

- Dispose of contaminated PPE as hazardous waste according to local regulations.

PPE Ergonomics and Comfort

Ensuring PPE is comfortable and ergonomically designed is essential for user acceptance and workplace safety. Comfortable PPE increases compliance, reduces the risk of injury, and enhances productivity.

Factors to Consider for PPE Comfort

- Fit and Sizing: Proper fit prevents discomfort, reduces the risk of slippage or accidents, and allows for ease of movement.

- Weight and Bulk: Heavy or bulky PPE can cause fatigue, strain, and discomfort, leading to reduced productivity.

- Ventilation and Breathability: PPE should allow for proper ventilation to prevent heat stress, skin irritation, and discomfort.

- Materials and Construction: Hypoallergenic and breathable materials reduce skin irritation and discomfort.

Tips for Improving PPE Ergonomics and Comfort

- Use adjustable PPE to accommodate different body sizes and shapes.

- Wear multiple layers of clothing under PPE for added warmth and comfort.

- Take regular breaks and stretch to prevent muscle strain and fatigue.

Consequences of Poor PPE Ergonomics and Comfort

- Reduced User Acceptance: Uncomfortable PPE is less likely to be worn, reducing protection and increasing the risk of injury.

- Increased Risk of Injury: Poorly fitting or uncomfortable PPE can interfere with movement, leading to accidents and injuries.

- Decreased Productivity: Discomfort and fatigue caused by uncomfortable PPE can reduce worker productivity.

Case Study

A manufacturing plant implemented a new line of ergonomic PPE for its employees. The new PPE was designed with lightweight materials, adjustable straps, and breathable fabrics. After implementation, employee complaints about discomfort decreased significantly, leading to increased PPE compliance, reduced injuries, and improved productivity.

PPE Technology and Innovation

The field of Personal Protective Equipment (PPE) is constantly evolving, with new advancements and innovations emerging regularly. These advancements are driven by the need to improve worker safety and comfort, while also addressing the challenges of emerging workplace hazards.

One of the most significant trends in PPE technology is the use of advanced materials. These materials are designed to provide better protection against specific hazards, while also being lighter and more comfortable to wear. For example, new types of fabrics are being developed that are resistant to cuts, punctures, and flames, while also being breathable and moisture-wicking.

Smart PPE

Another important area of innovation is the development of smart PPE. Smart PPE is equipped with sensors and other technology that can monitor the wearer’s health and safety. This information can be used to alert the wearer to potential hazards, or to provide feedback on how to improve their safety practices.

3D Printing

3D printing is also playing a role in the development of new PPE solutions. 3D printing allows for the creation of custom-fitted PPE that is tailored to the individual wearer. This can improve the comfort and effectiveness of PPE, while also reducing the risk of injury.

Examples of Innovative PPE Solutions

- Cut-resistant gloves made from high-performance fibers: These gloves provide excellent protection against cuts and punctures, while also being lightweight and flexible.

- Powered air-purifying respirators (PAPRs): PAPRs provide a high level of respiratory protection by filtering out airborne contaminants. They are often used in industrial settings where there is a risk of exposure to hazardous substances.

- Full-body suits made from lightweight, breathable materials: These suits provide protection against a variety of hazards, including chemicals, biological agents, and heat. They are often used in emergency response situations.

These are just a few examples of the many innovative PPE solutions that are available today. As technology continues to advance, we can expect to see even more innovative and effective PPE solutions in the future.

PPE Case Studies

Personal protective equipment (PPE) plays a crucial role in preventing workplace accidents and protecting employees’ health. Real-world case studies provide compelling evidence of the effectiveness of PPE in various industries.

These case studies offer valuable lessons on the importance of proper PPE usage, the consequences of non-compliance, and the positive impact of successful PPE implementation.

Examples of Successful PPE Implementation

- Construction Industry: In a construction project, workers were required to wear hard hats, safety glasses, and gloves. This PPE prevented serious head injuries, eye damage, and hand lacerations during a scaffolding collapse.

- Healthcare Industry: In a hospital, nurses and doctors were equipped with gloves, gowns, and masks to prevent the spread of infectious diseases. This PPE effectively reduced the risk of healthcare-associated infections among patients and staff.

- Manufacturing Industry: In a manufacturing plant, employees were provided with respirators, earplugs, and safety shoes. This PPE protected workers from harmful fumes, excessive noise, and foot injuries, preventing long-term health problems.

PPE Best Practices

Effective PPE management involves implementing best practices that ensure proper usage, maintenance, and continuous improvement. By following these guidelines, organizations can maximize the effectiveness of their PPE programs and enhance workplace safety.

Creating a Comprehensive PPE Program

- Conduct a comprehensive hazard assessment to identify potential risks and determine the appropriate PPE required.

- Establish clear policies and procedures for PPE selection, use, maintenance, and disposal.

- Provide training and education to employees on the proper use and care of PPE.

- Implement regular inspections and maintenance schedules to ensure PPE is in good condition.

- Establish a system for reporting and investigating PPE-related incidents.

Continuous Improvement of PPE Practices

To ensure the ongoing effectiveness of a PPE program, organizations should focus on continuous improvement.

- Regularly review and update PPE policies and procedures based on changes in regulations or industry best practices.

- Seek feedback from employees on the effectiveness and comfort of PPE.

- Explore new technologies and innovations that can enhance PPE protection.

- Conduct regular audits to assess the effectiveness of the PPE program and identify areas for improvement.

PPE Industry Trends

The PPE industry is constantly evolving to meet the changing needs of workers and workplaces. Some of the current and emerging trends in the PPE industry include:

- Advancements in materials and manufacturing techniques are leading to the development of lighter, more comfortable, and more durable PPE.

- The growing demand for specialized and niche PPE is being driven by the increasing complexity of workplace hazards.

- The rise of wearable technology and smart PPE is providing workers with new ways to monitor their safety and health.

These trends are being driven by a number of factors, including:

- Technological advancements are making it possible to develop new and innovative PPE materials and designs.

- Changing workplace regulations are requiring employers to provide workers with more comprehensive PPE.

- Evolving safety standards are raising the bar for PPE performance.

- Increasing awareness of workplace hazards is leading to greater demand for PPE.

The implications of these trends for the future of PPE are significant. The need for ongoing innovation and development will continue to drive the PPE industry forward. The potential for new market opportunities is vast, as new technologies and applications for PPE are discovered. The impact on workplace safety and productivity will be positive, as workers are better protected from workplace hazards.

Some of the key trends, drivers, implications, and future innovations in the PPE industry are summarized in the following table:

| Trend | Driver | Implication | Future Innovation |

|—|—|—|—|

| Advancements in materials and manufacturing techniques | Technological advancements | Lighter, more comfortable, and more durable PPE | New materials and manufacturing processes |

| Growing demand for specialized and niche PPE | Increasing complexity of workplace hazards | More specialized PPE to meet the needs of specific industries and hazards | Development of new PPE standards and regulations |

| The rise of wearable technology and smart PPE | Technological advancements | New ways to monitor worker safety and health | Integration of sensors and other technologies into PPE |

Actionable Insights for PPE Manufacturers and End-Users

- Invest in research and development to stay ahead of the curve on new PPE technologies and materials.

- Develop specialized PPE to meet the needs of specific industries and hazards.

- Explore the use of wearable technology and smart PPE to improve worker safety and health.

- Work with end-users to identify and address their PPE needs.

- Educate workers on the importance of PPE and how to use it properly.

The trends discussed in this section are likely to have a significant impact on the broader occupational safety and health landscape. As PPE becomes more advanced and effective, workers will be better protected from workplace hazards. This will lead to a reduction in workplace injuries and illnesses, and a corresponding increase in productivity and economic growth.

PPE Resources

PPE information and support are readily available through various resources. These resources provide valuable insights, guidelines, and best practices to help individuals and organizations enhance their PPE knowledge and implementation.

Accessing Resources

Accessing these resources is straightforward. Many of them are available online, while others can be obtained through libraries, professional organizations, or industry events. It is important to evaluate the credibility and reliability of the resources before utilizing them.

List of Resources

The following table provides a list of valuable PPE resources, including websites, organizations, and publications:

| Resource Name | Description | Link |

|---|---|---|

| National Institute for Occupational Safety and Health (NIOSH) | Provides comprehensive information on PPE, including standards, hazard assessment, and training. | https://www.cdc.gov/niosh/ |

| Occupational Safety and Health Administration (OSHA) | Enforces workplace safety regulations, including PPE requirements. | https://www.osha.gov/ |

| American National Standards Institute (ANSI) | Develops and publishes consensus standards for PPE. | https://www.ansi.org/ |

| International Safety Equipment Association (ISEA) | Represents manufacturers and suppliers of PPE. | https://www.safetyequipment.org/ |

| National Safety Council (NSC) | Promotes workplace safety and health, including PPE use. | https://www.nsc.org/ |

Each resource listed above offers unique information and support tailored to different audiences and needs. By utilizing these resources, individuals and organizations can stay up-to-date on the latest PPE standards, best practices, and industry trends.

PPE Glossary

The field of Personal Protective Equipment (PPE) involves a range of specialized terms and concepts. This glossary provides a comprehensive list of PPE-related terms and their clear and concise definitions, serving as a valuable reference for professionals and individuals seeking to enhance their understanding of PPE.

Understanding the key concepts and terminology used in PPE is crucial for effective implementation, compliance, and overall safety in workplaces. This glossary aims to clarify and demystify the technical language surrounding PPE, enabling users to engage confidently in discussions, decision-making, and best practices related to PPE.

PPE Types

- Respiratory Protective Equipment (RPE): PPE designed to protect the wearer’s respiratory system from hazardous substances, such as dust, fumes, gases, and vapors.

- Eye and Face Protection: PPE that shields the wearer’s eyes and face from hazards such as flying particles, chemicals, and radiation.

- Head Protection: PPE that safeguards the wearer’s head from impact, penetration, and electrical hazards.

- Hearing Protection: PPE that reduces the level of noise reaching the wearer’s ears, protecting against hearing loss.

- Hand Protection: PPE that covers the wearer’s hands and protects them from chemical, mechanical, and thermal hazards.

- Foot Protection: PPE that covers the wearer’s feet and protects them from hazards such as impact, puncture, and slips.

- Body Protection: PPE that covers the wearer’s body and protects them from hazards such as chemicals, heat, and cold.

PPE Standards and Regulations

- ANSI: American National Standards Institute, which develops and publishes standards for PPE.

- OSHA: Occupational Safety and Health Administration, which regulates PPE use in the United States.

- NIOSH: National Institute for Occupational Safety and Health, which conducts research and provides guidance on PPE.

- CE: Conformité Européenne, a marking that indicates that a product meets European safety standards.

PPE Hazard Assessment

- Hazard: A potential source of harm or injury.

- Risk: The likelihood and severity of harm or injury occurring from a hazard.

- PPE Hazard Assessment: The process of identifying and evaluating hazards in the workplace and determining the appropriate PPE to mitigate those hazards.

PPE Training and Education

- PPE Training: Instruction and practice on the proper selection, use, and maintenance of PPE.

- PPE Education: Awareness and understanding of the importance and benefits of PPE, as well as the consequences of not using PPE.

PPE Maintenance and Inspection

- PPE Maintenance: Regular cleaning, repair, and replacement of PPE to ensure its effectiveness.

- PPE Inspection: Regular examination of PPE to identify any damage or defects.

PPE Storage and Disposal

- PPE Storage: Proper storage of PPE to protect it from damage and contamination.

- PPE Disposal: Safe and responsible disposal of PPE at the end of its useful life.

PPE Ergonomics and Comfort

- PPE Ergonomics: The design and use of PPE to minimize discomfort and fatigue for the wearer.

- PPE Comfort: The level of physical and psychological comfort experienced by the wearer while using PPE.

PPE Technology and Innovation

- PPE Technology: Advancements in materials, design, and manufacturing of PPE to improve its effectiveness and comfort.

- PPE Innovation: New and emerging PPE solutions that address evolving workplace hazards and challenges.

PPE Case Studies

- PPE Case Studies: Real-world examples of the successful use of PPE in preventing workplace injuries and illnesses.

PPE Best Practices

- PPE Best Practices: Recommended guidelines and strategies for the effective use and management of PPE.

PPE Industry Trends

- PPE Industry Trends: Emerging trends and developments in the PPE industry, including new technologies, regulations, and best practices.

PPE Resources

- PPE Resources: A collection of valuable resources, such as websites, articles, and organizations, that provide further information on PPE.

Last Recap

By embracing a proactive approach to PPE usage and management, organizations can create a safer and healthier work environment, fostering productivity, reducing costs, and safeguarding their most valuable assets – their employees.