John Amos Power Plant stands as a beacon of technological advancement and environmental stewardship, shaping the future of energy production with its groundbreaking innovations and unwavering commitment to sustainability.

Established in 1975, the plant has undergone a series of upgrades and modernizations, transforming it into a state-of-the-art facility that sets new standards for efficiency, reliability, and environmental protection.

Plant History and Operations

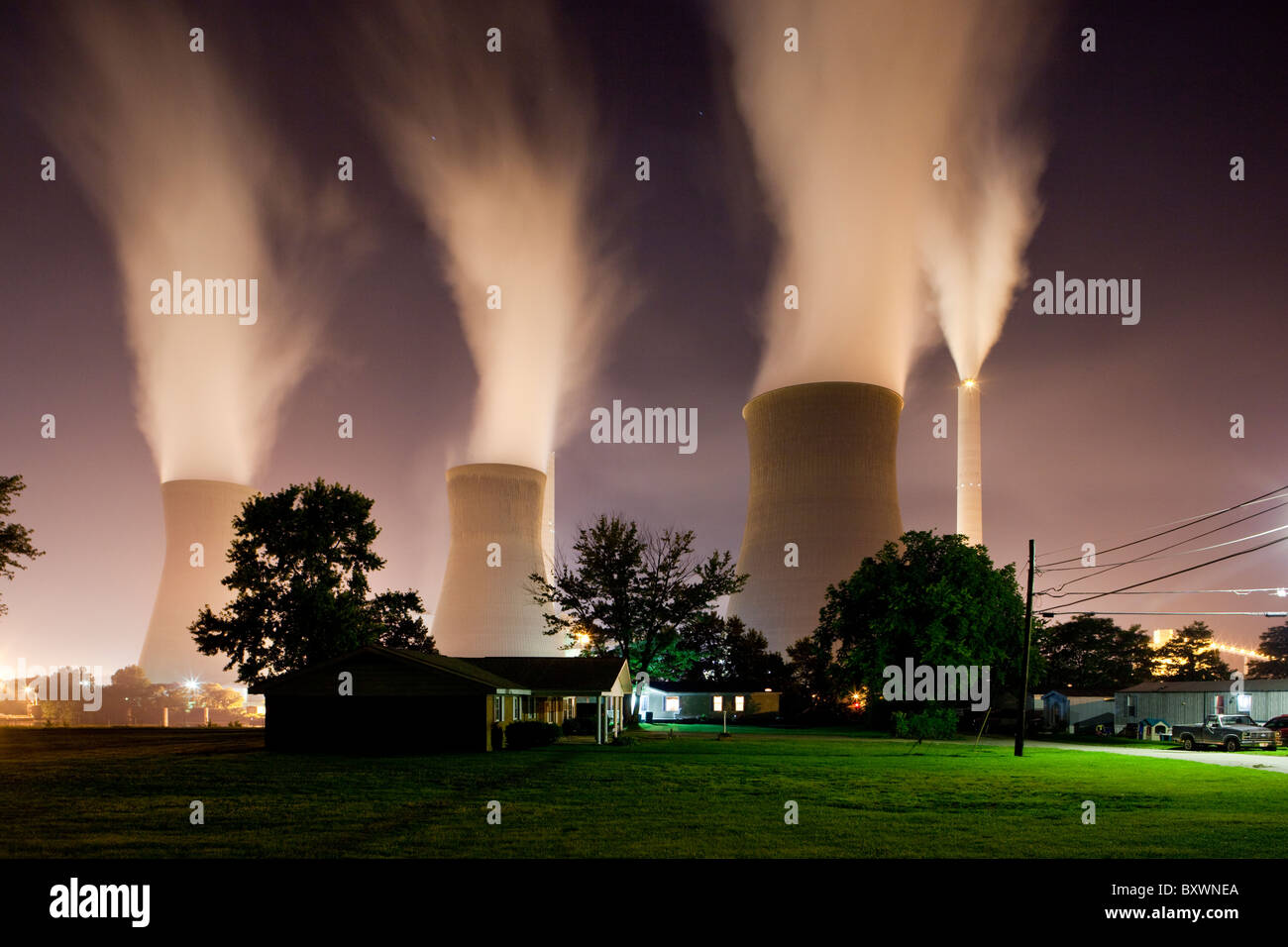

The John Amos Power Plant, situated in Winfield, West Virginia, stands as a testament to the evolving landscape of energy generation. Its history is intertwined with advancements in technology and the ever-growing demand for electricity.

The plant’s genesis can be traced back to the early 1950s, when the Appalachian Power Company embarked on a project to construct a coal-fired power plant to meet the burgeoning energy needs of the region. In 1955, the first unit of the John Amos Power Plant commenced operations, marking the beginning of its long and impactful history.

Construction and Upgrades

The John Amos Power Plant underwent several major upgrades and expansions over the years to enhance its efficiency and capacity. In 1963, a second unit was added, followed by a third unit in 1973. These additions significantly increased the plant’s electricity generation capabilities.

In the 1980s, the plant underwent a major modernization program that involved the installation of state-of-the-art pollution control equipment. These upgrades not only reduced the plant’s environmental impact but also improved its operational efficiency.

Current Operations

Today, the John Amos Power Plant operates as a three-unit coal-fired power plant with a combined generating capacity of approximately 1,800 megawatts. The plant plays a vital role in meeting the baseload electricity needs of West Virginia and the surrounding region.

The plant primarily utilizes coal as its fuel source, with a small portion of natural gas used for startup and peak load operations. The plant’s environmental impact is carefully monitored and mitigated through the use of advanced pollution control technologies.

Role in the Energy Grid

The John Amos Power Plant is an integral part of the regional energy grid, providing a reliable and affordable source of electricity to millions of homes and businesses. The plant’s location within the coal-rich Appalachian region ensures a stable and cost-effective fuel supply.

The plant’s flexible operations allow it to adjust its output to meet varying electricity demands throughout the day and year. This flexibility is crucial for maintaining the stability and reliability of the regional energy grid.

Technological Innovations and Advancements: John Amos Power Plant

The John Amos Power Plant has implemented several technological innovations and advancements to improve its efficiency, reduce its environmental impact, and enhance its reliability. These advancements include the use of supercritical boilers, flue gas desulfurization systems, and selective catalytic reduction systems.

Supercritical Boilers

Supercritical boilers operate at pressures and temperatures above the critical point of water, which allows for more efficient heat transfer and steam generation. This results in increased plant efficiency and reduced fuel consumption. The John Amos Power Plant uses supercritical boilers to generate steam for its turbines, which has significantly improved the plant’s overall efficiency.

Flue Gas Desulfurization Systems, John amos power plant

Flue gas desulfurization systems (FGDs) are used to remove sulfur dioxide (SO2) from the exhaust gases of power plants. SO2 is a major air pollutant that can cause respiratory problems and contribute to acid rain. The John Amos Power Plant uses wet FGD systems, which spray a limestone slurry into the exhaust gases to absorb the SO2. The resulting sludge is then removed and disposed of.

Selective Catalytic Reduction Systems

Selective catalytic reduction systems (SCRs) are used to remove nitrogen oxides (NOx) from the exhaust gases of power plants. NOx is a major air pollutant that can contribute to smog and respiratory problems. The John Amos Power Plant uses SCRs to inject ammonia into the exhaust gases, which reacts with the NOx to form nitrogen and water.

Environmental Considerations and Sustainability Initiatives

The John Amos Power Plant operates responsibly and takes proactive measures to minimize its environmental impact while ensuring reliable energy production. The plant adheres to stringent environmental regulations and implements various sustainability initiatives to reduce emissions, conserve resources, and protect the surrounding ecosystem.

Air Emissions Reduction

The plant utilizes advanced emission control technologies to mitigate air pollution. Flue gas desulfurization (FGD) systems effectively remove sulfur dioxide (SO2) emissions, while selective catalytic reduction (SCR) systems significantly reduce nitrogen oxide (NOx) emissions. These technologies ensure that the plant meets or exceeds air quality standards, contributing to cleaner air for the local community.

Water Conservation and Management

Water conservation is a critical aspect of the plant’s operations. The plant employs closed-loop cooling systems that minimize water consumption. Additionally, the plant treats wastewater through a state-of-the-art water treatment facility, ensuring that discharged water meets or exceeds environmental standards.

Waste Management and Recycling

The plant implements comprehensive waste management practices to reduce its environmental footprint. Solid waste is recycled or disposed of responsibly, while hazardous waste is handled and disposed of in accordance with regulations. The plant’s commitment to waste minimization and recycling helps conserve resources and protect the environment.

Land Use and Habitat Conservation

The plant is located on a site that has been carefully selected to minimize its impact on the surrounding ecosystem. The plant has implemented measures to protect and preserve wildlife habitats, including the establishment of natural buffers and the use of native plant species in landscaping.

Community Outreach and Education

The John Amos Power Plant actively engages with the local community through outreach programs and educational initiatives. The plant provides tours and presentations to raise awareness about energy production and environmental stewardship. The plant also supports local environmental organizations and initiatives, demonstrating its commitment to sustainable community development.

Environmental Compliance and Reporting

The John Amos Power Plant is fully compliant with all applicable environmental regulations and regularly reports its environmental performance to regulatory agencies. The plant’s commitment to transparency and accountability ensures that it operates in an environmentally responsible manner.