The Morro Bay Power Plant, a prominent landmark on California’s Central Coast, stands as a testament to the complexities of energy production and environmental stewardship. This coal-fired power plant has generated electricity for decades, while also facing scrutiny for its environmental impact. In this exploration, we delve into the history, operations, and ongoing challenges of the Morro Bay Power Plant, uncovering the interplay between energy needs and environmental concerns.

Commissioned in 1958, the Morro Bay Power Plant initially operated with four coal-fired units, with two additional units added in the 1970s. The plant’s proximity to the ocean provided access to cooling water, but also raised concerns about thermal pollution and the impact on marine life. Over the years, the plant has undergone upgrades and retrofits to reduce emissions, including the installation of pollution control devices and the use of cleaner-burning coal.

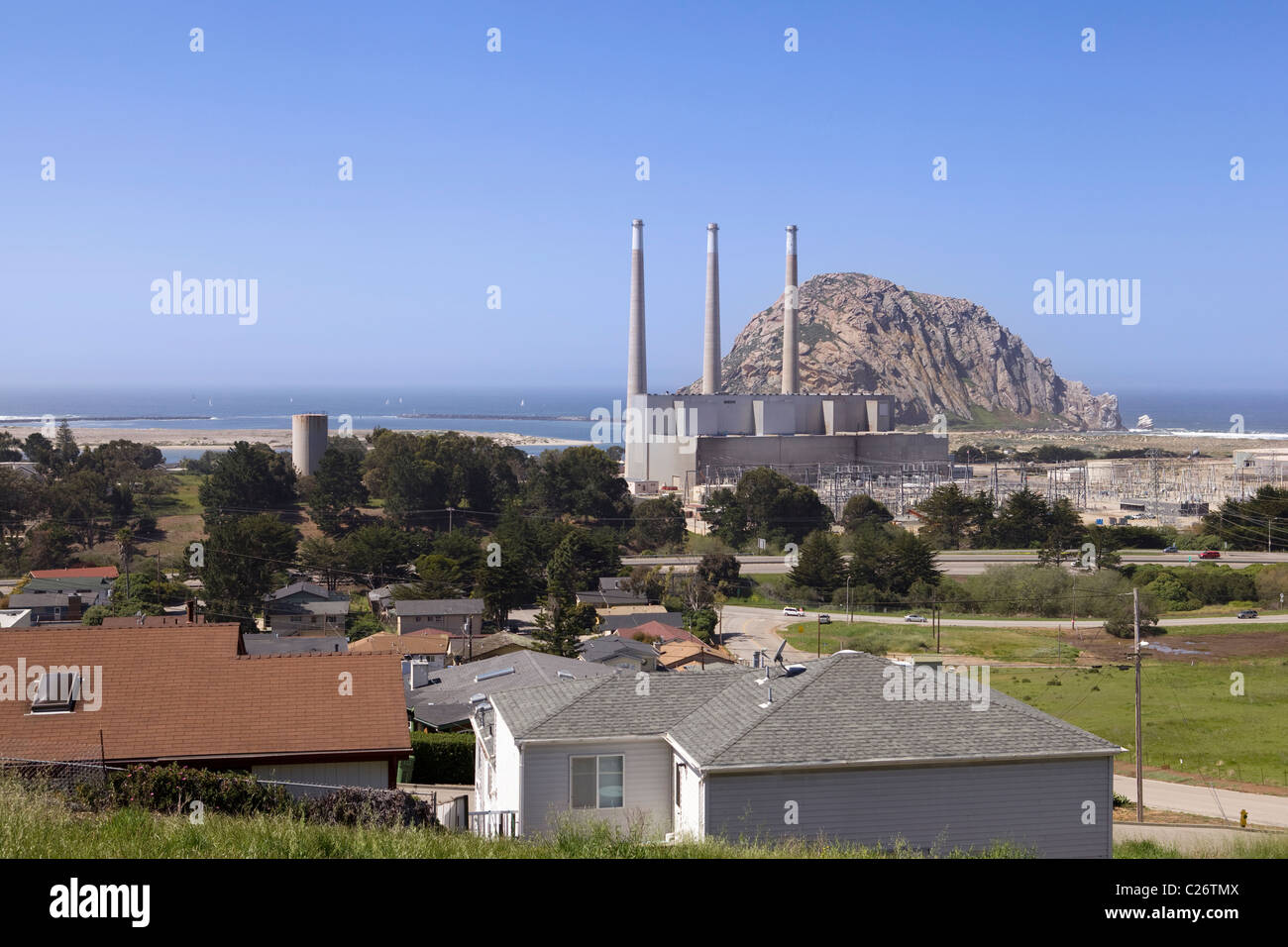

Morro Bay Power Plant Overview

The Morro Bay Power Plant is a natural gas-fired power plant located in Morro Bay, California. It is owned and operated by Pacific Gas and Electric Company (PG&E). The plant has a generating capacity of 1,000 megawatts (MW) and provides electricity to approximately 1 million customers in central and northern California.

The plant was built in the early 1950s and has been expanded and upgraded several times since then. The most recent expansion was completed in 2010 and added a new combined-cycle unit to the plant. The combined-cycle unit uses natural gas to generate electricity and then uses the waste heat from the process to generate additional electricity.

Environmental Impact

The Morro Bay Power Plant has a significant environmental impact. The plant emits greenhouse gases, which contribute to climate change. The plant also emits air pollutants, such as nitrogen oxides and sulfur oxides, which can cause respiratory problems and other health issues.

PG&E has taken steps to reduce the environmental impact of the Morro Bay Power Plant. The plant has installed pollution control equipment and has switched to using natural gas as its primary fuel source. These measures have helped to reduce the plant’s emissions by approximately 90% since the 1950s.

Community Involvement

The Morro Bay Power Plant is an important part of the local community. The plant provides jobs for hundreds of people and generates tax revenue for the city of Morro Bay. PG&E also supports a variety of community programs, including scholarships, environmental education, and arts and culture events.

The Morro Bay Power Plant is a complex and controversial facility. However, it is also an important part of the local community and provides electricity to millions of Californians.

Energy Production and Distribution: Morro Bay Power Plant

The Morro Bay Power Plant generates electricity through a process called combined-cycle power generation. This process involves burning natural gas to produce steam, which drives a turbine that generates electricity. The plant’s two generators have a combined capacity of 1,600 megawatts (MW), making it one of the largest power plants in California.

Fuel Types and Efficiency

The Morro Bay Power Plant primarily uses natural gas as fuel. Natural gas is a clean-burning fossil fuel that produces fewer emissions than other fossil fuels, such as coal or oil. The plant also has the capability to use ultra-low-sulfur diesel fuel as a backup fuel.

The Morro Bay Power Plant has an overall efficiency of approximately 55%. This means that for every unit of fuel burned, 55% of the energy is converted into electricity. The remaining 45% of the energy is lost as heat.

Energy Production and Distribution

The Morro Bay Power Plant produces enough electricity to power approximately 1.5 million homes. The electricity is distributed to homes and businesses in the surrounding area through a network of transmission lines.

In addition to generating electricity, the Morro Bay Power Plant also provides district heating to the nearby community. District heating is a system that uses hot water or steam to heat homes and businesses. The hot water or steam is generated at the power plant and then distributed through a network of pipes to the surrounding area.

Technological Advancements and Innovations

The Morro Bay Power Plant has embraced cutting-edge technologies to enhance its efficiency, reduce emissions, and ensure safety. These advancements include the utilization of advanced combustion systems, state-of-the-art emission control technologies, and sophisticated monitoring and control systems.

Advanced Combustion Systems

The plant employs modern combustion systems, such as low-NOx burners and over-fire air systems, which optimize the combustion process to reduce the formation of harmful nitrogen oxides (NOx). These systems ensure that fuel is burned more efficiently, leading to lower emissions and increased energy output.

Emission Control Technologies

The Morro Bay Power Plant has implemented a comprehensive suite of emission control technologies to minimize its environmental impact. These include:

- Selective Catalytic Reduction (SCR) System: An SCR system injects urea into the exhaust gas stream, converting NOx into harmless nitrogen and water vapor.

- Flue Gas Desulfurization (FGD) System: An FGD system removes sulfur dioxide (SO2) from the exhaust gas stream, reducing acid rain and improving air quality.

- Electrostatic Precipitators (ESPs): ESPs remove particulate matter from the exhaust gas stream, reducing emissions of soot and other pollutants.

Monitoring and Control Systems, Morro bay power plant

Advanced monitoring and control systems at the Morro Bay Power Plant ensure efficient and safe operation. These systems include:

- Distributed Control System (DCS): A DCS provides real-time monitoring and control of all plant operations, enabling operators to respond quickly to changes and optimize performance.

- Continuous Emissions Monitoring System (CEMS): A CEMS monitors emissions levels continuously, ensuring compliance with environmental regulations and providing data for performance analysis.

The integration of these cutting-edge technologies has transformed the Morro Bay Power Plant into a highly efficient and environmentally responsible energy producer.