Plant layout and design is the art of arranging physical facilities, equipment, and personnel to maximize productivity and efficiency. By understanding the principles and factors involved, industries can create optimal layouts that drive operational success.

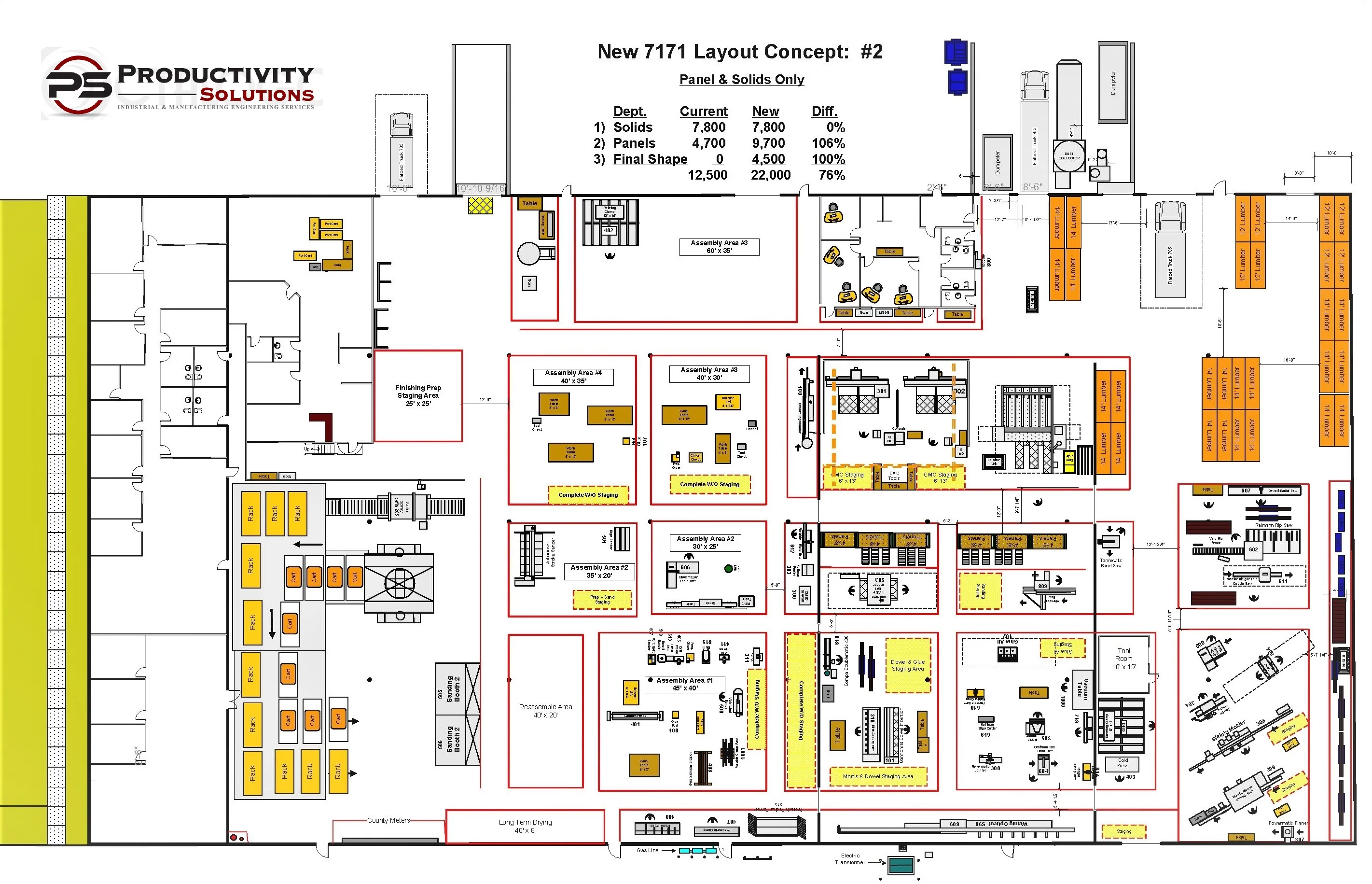

From process-oriented layouts to product-focused designs, the type of layout chosen depends on specific industry needs and constraints. Factors such as product flow, equipment requirements, and space limitations play a crucial role in shaping the overall layout.

Factors Influencing Plant Layout Design: Plant Layout And Design

Plant layout design is a critical aspect of manufacturing operations, influencing efficiency, productivity, and overall profitability. Several key factors must be considered and prioritized during the design process to optimize the layout and achieve desired outcomes.

Product Flow

The flow of products through the production process significantly impacts the plant layout. The layout should facilitate a smooth and efficient flow of materials, minimizing bottlenecks and delays. Factors to consider include the sequence of operations, the volume and type of products, and the need for flexibility to accommodate product variations.

Equipment Requirements, Plant layout and design

The type and size of equipment used in the production process dictate specific space requirements and layout considerations. Factors to consider include the dimensions and shape of the equipment, the need for specialized utilities (e.g., power, water, gas), and the required clearances for maintenance and operation.

Space Constraints

The available space for the plant layout imposes limitations and opportunities. Factors to consider include the size and shape of the building, the presence of existing structures or obstacles, and the need for future expansion. The layout should maximize space utilization while ensuring adequate space for production activities, material storage, and employee movement.

Plant layout and design encompass various elements to optimize plant growth and productivity. Coco fiber plant liners, made from the fibrous husk of coconuts ( coco fiber plant liners ), offer exceptional benefits for plant health. These liners provide aeration and drainage, ensuring healthy root development.

By incorporating coco fiber plant liners into the design, plant layout can be optimized to promote vigorous plant growth and enhance overall plant performance.

In the realm of plant layout and design, meticulous consideration is given to each element, from the arrangement of equipment to the selection of plant species. Among the diverse flora, the five finger grass plant stands out for its unique characteristics.

Its ability to thrive in various environments and its aesthetic appeal make it a versatile choice for landscape architects. As we delve deeper into plant layout and design, we recognize the significance of integrating botanical diversity and functionality, ensuring that each element contributes to the overall harmony and purpose of the space.

The plant layout and design are critical factors in determining the efficiency and productivity of a manufacturing facility. One example of a well-designed plant is the st wooten asphalt plant . This plant features a state-of-the-art layout that optimizes the flow of materials and minimizes downtime.

The plant’s efficient design has helped it to become one of the leading asphalt plants in the industry. Plant layout and design play a significant role in the success of any manufacturing operation, and the st wooten asphalt plant is a prime example of how a well-designed plant can lead to increased efficiency and productivity.