The Leon Creek Power Plant stands as a testament to human ingenuity and the ever-evolving pursuit of efficient energy generation. Nestled in the heart of Texas, this power plant has played a pivotal role in meeting the growing energy demands of the region while embracing technological advancements that minimize environmental impact.

Over the years, the Leon Creek Power Plant has undergone a series of upgrades and retrofits, each designed to enhance its efficiency and reduce its emissions. Today, the plant utilizes state-of-the-art combustion technologies, emissions control systems, and advanced monitoring systems to ensure optimal performance.

Overview of Leon Creek Power Plant

The Leon Creek Power Plant, located in San Antonio, Texas, is a coal-fired power plant that has been in operation since 1960. It is owned and operated by the San Antonio City Public Service (CPS Energy). The plant has a capacity of 1,240 megawatts (MW) and provides electricity to over 750,000 customers in the San Antonio area.

The Leon Creek Power Plant has been a major source of electricity for San Antonio for over 60 years. However, it has also been a major source of pollution. The plant emits large amounts of sulfur dioxide, nitrogen oxides, and particulate matter, which can contribute to respiratory problems and other health issues. In recent years, CPS Energy has taken steps to reduce the environmental impact of the Leon Creek Power Plant. The plant has been retrofitted with pollution control equipment, and CPS Energy has also invested in renewable energy sources such as solar and wind power.

Environmental Impact, Leon creek power plant

The Leon Creek Power Plant has a significant environmental impact. The plant emits large amounts of sulfur dioxide, nitrogen oxides, and particulate matter, which can contribute to respiratory problems and other health issues. The plant also uses a large amount of water, which can put a strain on local water resources.

CPS Energy has taken steps to reduce the environmental impact of the Leon Creek Power Plant. The plant has been retrofitted with pollution control equipment, and CPS Energy has also invested in renewable energy sources such as solar and wind power. As a result of these efforts, the plant’s emissions have been reduced by over 90% since the 1970s.

Despite the progress that has been made, the Leon Creek Power Plant remains a major source of pollution. CPS Energy is currently considering retiring the plant by 2028. This would be a significant step towards reducing the environmental impact of the power plant.

Technological Advancements: Leon Creek Power Plant

The Leon Creek Power Plant has implemented cutting-edge technological advancements to enhance its efficiency, reduce emissions, and improve safety. These advancements have transformed the plant into a leader in the power generation industry, setting new benchmarks for environmental performance and operational excellence.

Emission Control Systems

The plant has invested in advanced emission control systems to minimize its environmental impact. These systems include:

- Selective Catalytic Reduction (SCR): SCR systems use ammonia to reduce nitrogen oxides (NOx) emissions by up to 90%.

- Flue Gas Desulfurization (FGD): FGD systems remove sulfur dioxide (SO2) from the flue gas, reducing acid rain and smog.

- Electrostatic Precipitators (ESPs): ESPs remove particulate matter (PM) from the flue gas, improving air quality.

These systems have significantly reduced the plant’s emissions, meeting or exceeding the most stringent environmental regulations.

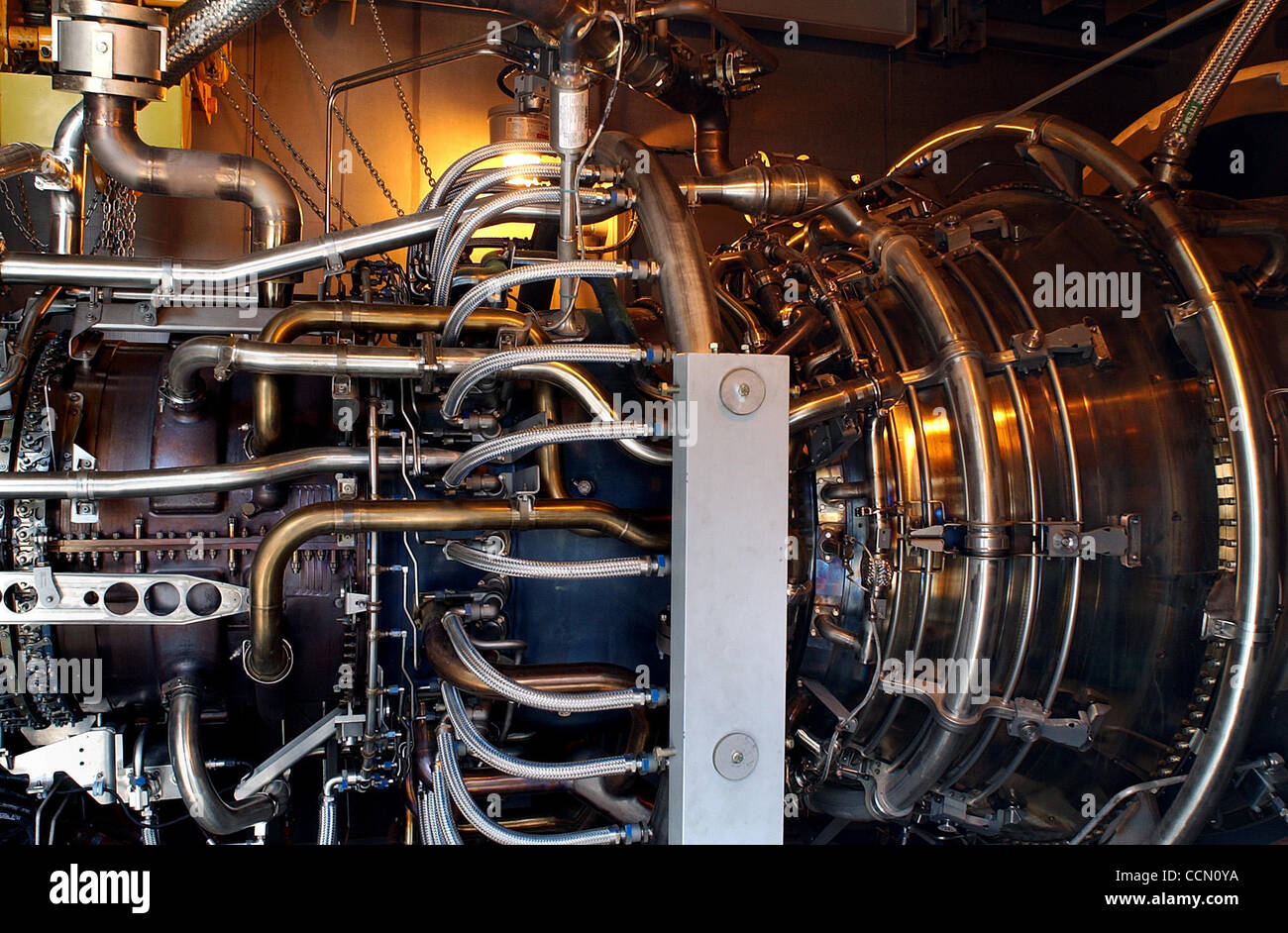

Turbine Upgrades

The plant has upgraded its turbines with advanced technologies to improve efficiency and reduce emissions. These upgrades include:

- Advanced Combustion Systems: These systems optimize the fuel-air mixture, resulting in more efficient combustion and lower emissions.

- Variable Speed Generators: These generators adjust their speed to match the grid demand, reducing fuel consumption and emissions.

- Advanced Control Systems: These systems monitor and control the plant’s operations in real-time, optimizing performance and reducing emissions.

These turbine upgrades have significantly improved the plant’s efficiency, reducing its carbon footprint and operating costs.

Safety Enhancements

The plant has implemented numerous safety enhancements to protect its employees and the surrounding community. These enhancements include:

- Advanced Fire Detection and Suppression Systems: These systems detect and suppress fires quickly, minimizing the risk of accidents.

- Emergency Response Plans: The plant has comprehensive emergency response plans in place to address any potential incidents.

- Employee Training Programs: Employees receive ongoing training on safety procedures and best practices.

These safety enhancements have created a safer work environment and reduced the risk of accidents and injuries.

Future Plans and Developments

The Leon Creek Power Plant has several future plans and developments in store. These include:

Expansion Projects

The plant is currently undergoing a major expansion project that will add a new natural gas-fired combined cycle unit to the facility. The new unit will have a capacity of 800 megawatts (MW) and is expected to be completed in 2024. This expansion will increase the plant’s total capacity to over 2,000 MW.

Upgrades

In addition to the expansion project, the plant is also planning to upgrade its existing coal-fired units. These upgrades will include the installation of new pollution control equipment and the replacement of old equipment with more efficient models. The upgrades are expected to reduce the plant’s emissions and improve its efficiency.

Changes in Fuel Source

The Leon Creek Power Plant is currently exploring the possibility of switching to a different fuel source. The plant is considering using natural gas, biomass, or solar power as a replacement for coal. This change would reduce the plant’s emissions and help it to meet the state’s renewable energy goals.

Potential Impact

The future plans and developments for the Leon Creek Power Plant have the potential to have a significant impact on the local community and environment. The expansion project will create new jobs and boost the local economy. The upgrades to the existing units will reduce the plant’s emissions and improve its efficiency. And the change in fuel source would further reduce the plant’s emissions and help it to meet the state’s renewable energy goals.