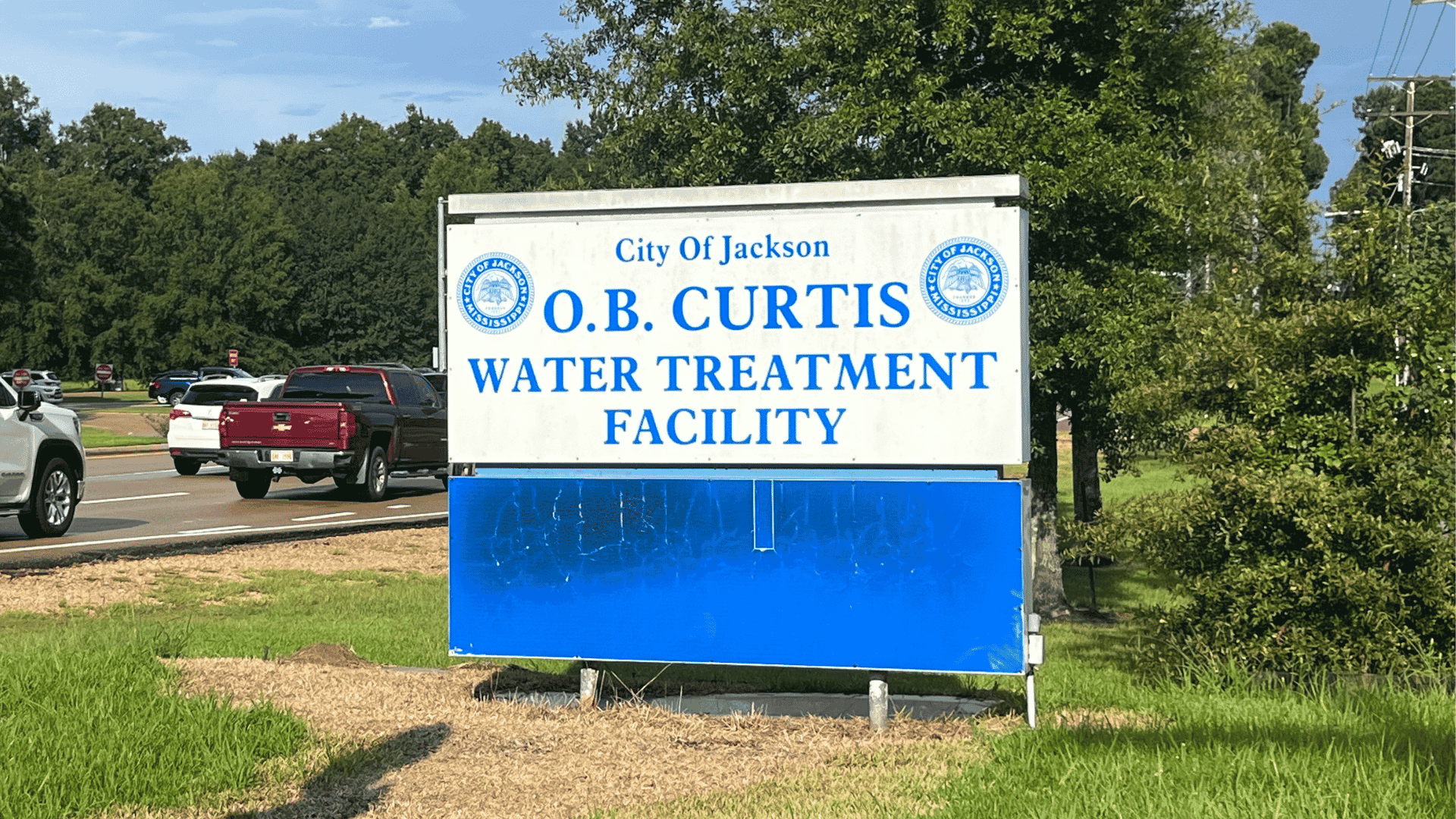

O b curtis water plant – At the heart of a vibrant community, the O.B. Curtis Water Plant stands as a testament to human ingenuity and environmental stewardship. Its journey, spanning decades of innovation and unwavering commitment to providing clean, safe water, is a captivating tale that intertwines scientific prowess with a profound respect for the natural world.

Established in the year 1954, the plant has grown to become a cornerstone of the region’s water infrastructure, serving a population of over 1 million residents. Its impressive capacity of treating 300 million gallons of water daily ensures a steady supply of potable water to homes, businesses, and industries alike.

O.B. Curtis Water Plant Overview

The O.B. Curtis Water Plant, a state-of-the-art water treatment facility, plays a pivotal role in providing a reliable supply of clean and safe drinking water to the residents of the Greater Boston area.

Established in 1978, the plant has undergone significant expansions and upgrades over the years to meet the growing water demands of the region. Today, it is one of the largest and most advanced water treatment facilities in the United States.

Capacity and Water Sources

The O.B. Curtis Water Plant has a maximum treatment capacity of 240 million gallons of water per day. It draws its raw water from the Quabbin Reservoir, the largest public water supply in Massachusetts, and the Wachusett Reservoir, the second largest.

Service Area

The treated water from the O.B. Curtis Water Plant is distributed to over 2.5 million people in 35 cities and towns in the Greater Boston area, including Boston, Cambridge, Somerville, and Quincy.

Water Treatment Processes and Technology: O B Curtis Water Plant

The O.B. Curtis Water Plant utilizes a comprehensive array of water treatment processes and cutting-edge technologies to ensure the delivery of safe and high-quality drinking water to its customers. These processes are meticulously designed to remove impurities, enhance water clarity, and safeguard public health.

Coagulation and Flocculation

Coagulation and flocculation are crucial initial steps in water treatment. Coagulation involves the addition of coagulants, such as aluminum or iron salts, which destabilize impurities and cause them to clump together. Flocculation then gently agitates the water, allowing these clumps (flocs) to collide and form larger, more easily removable particles.

Sedimentation

Sedimentation is a gravity-driven process where the flocs settle to the bottom of sedimentation basins. The heavier particles sink and accumulate as sludge, while the clarified water rises to the surface for further treatment.

Filtration

Filtration is a physical process that removes remaining impurities by passing the water through layers of granular media, such as sand, anthracite, and garnet. These media trap particles based on their size and charge, further enhancing water clarity.

Disinfection

Disinfection is the final stage of water treatment and is essential for eliminating harmful microorganisms. The O.B. Curtis Water Plant primarily uses chlorination, where chlorine is added to the water to kill bacteria and viruses. Other disinfection methods, such as ozonation and ultraviolet (UV) irradiation, may also be employed.

Advanced Technologies, O b curtis water plant

The O.B. Curtis Water Plant employs advanced technologies to optimize water treatment efficiency and ensure consistent water quality. These technologies include:

- Automated control systems that monitor and adjust treatment processes in real-time, ensuring optimal performance.

- Membrane filtration systems, such as microfiltration and ultrafiltration, which remove even smaller particles and microorganisms.

- Advanced oxidation processes (AOPs), which utilize oxidants like ozone and hydrogen peroxide to break down recalcitrant contaminants.

Sustainability and Environmental Impact

/cloudfront-us-east-1.images.arcpublishing.com/gray/4SCQGNGBFNDQDNMF6E3CST2E6E.png)

The O.B. Curtis Water Plant is committed to sustainability and environmental protection. The plant has implemented various measures to minimize its environmental impact and protect water resources.

To reduce energy consumption, the plant uses energy-efficient technologies, such as variable frequency drives on pumps and motors. The plant also has a solar array that generates renewable energy. To reduce waste, the plant recycles materials and uses recycled materials in construction and maintenance.

Water Resources Protection

The O.B. Curtis Water Plant plays a vital role in protecting water resources. The plant uses advanced treatment technologies to remove contaminants from water, ensuring that the water meets or exceeds drinking water standards. The plant also monitors water quality and quantity to ensure that the water is safe for consumption.

Ecosystem Preservation

The O.B. Curtis Water Plant is located in a sensitive ecosystem. The plant has taken steps to minimize its impact on the environment, such as using native plants in landscaping and reducing noise pollution.