Unveiling the Viscose Plant Roanoke VA: Embark on a captivating journey through history, innovation, and global impact, where the production of this versatile material has shaped industries and communities alike.

From its humble beginnings to its cutting-edge advancements, the viscose plant in Roanoke, Virginia, stands as a testament to human ingenuity and the transformative power of science.

Viscose Plant History and Significance: Viscose Plant Roanoke Va

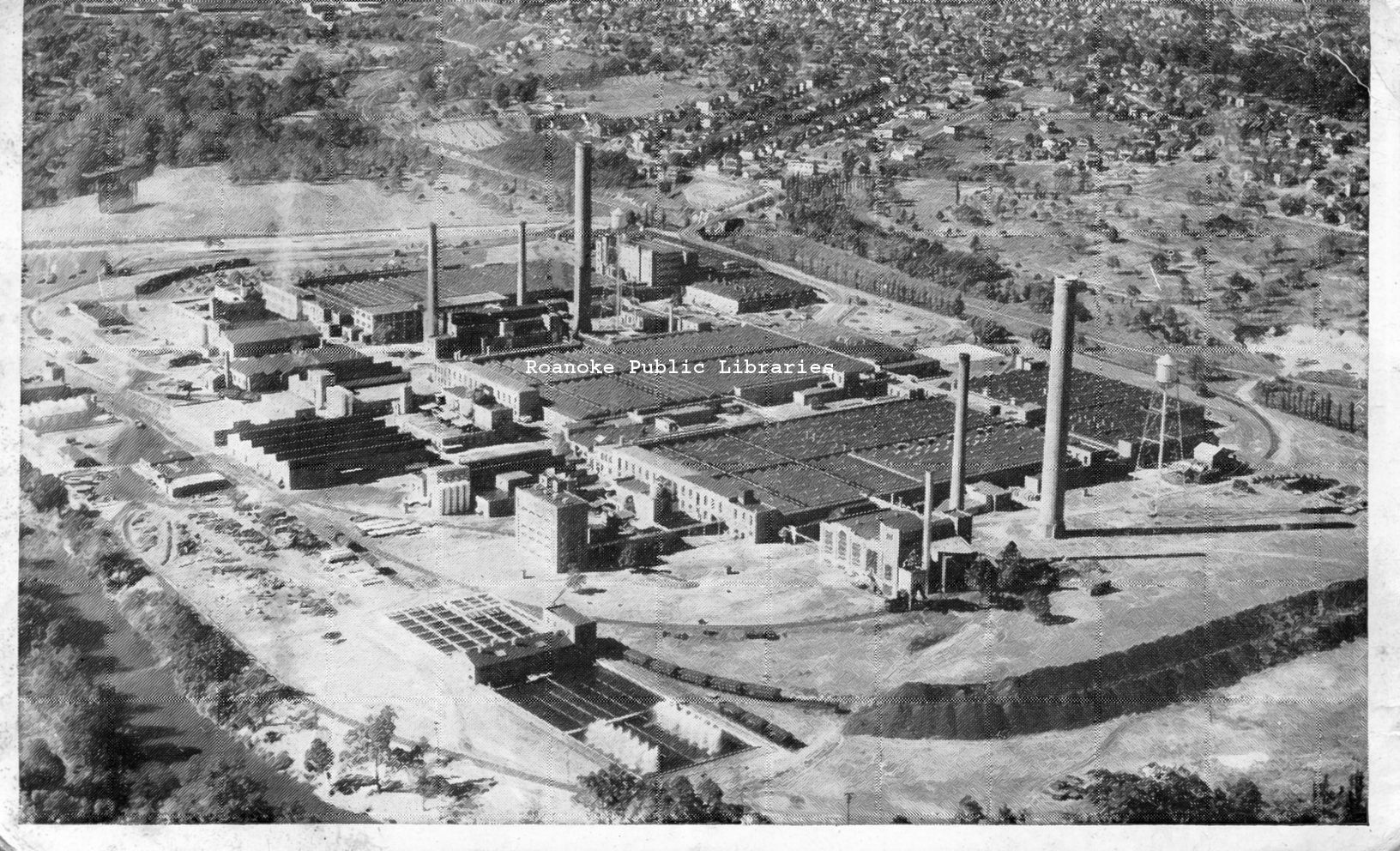

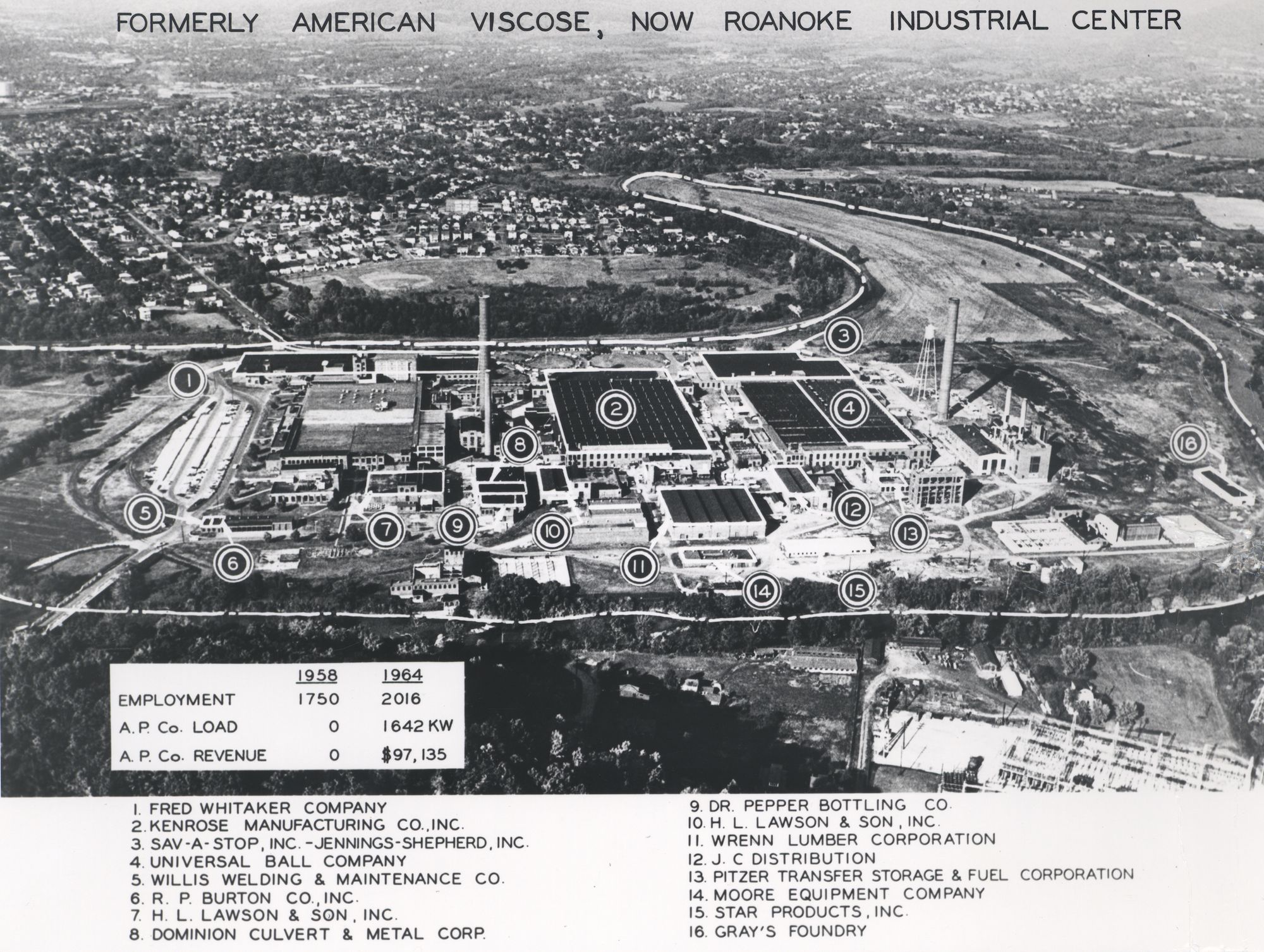

The viscose plant in Roanoke, Virginia, has a rich history that dates back to the early 20th century. Established in 1917 as the American Viscose Corporation, the plant was a major producer of viscose rayon, a synthetic fiber used in a wide range of products, including clothing, textiles, and tire cords. The plant played a significant role in the local economy, providing employment for thousands of workers and contributing to the growth of the Roanoke Valley.

The former viscose plant in Roanoke, Virginia, once a hub for textile production, now stands as a testament to the evolution of industry. As the world shifts towards renewable energy sources, the site could potentially be repurposed for a solar power plant.

Solar power plant design involves optimizing the arrangement of photovoltaic panels to maximize sunlight absorption and energy generation. The vast expanse of the former viscose plant provides an ideal location for such a project, contributing to Roanoke’s transition towards a sustainable future.

Over the years, the viscose plant has undergone numerous technological advancements and innovations. In the 1950s, the plant began using a new continuous spinning process that significantly increased production efficiency. In the 1970s, the plant installed a state-of-the-art wastewater treatment facility to reduce its environmental impact. Today, the viscose plant continues to operate as a modern and efficient facility, producing high-quality viscose rayon for a variety of applications.

Impact on the Local Economy and Community, Viscose plant roanoke va

The viscose plant has had a major impact on the local economy and community. The plant has been a major employer in the Roanoke Valley for over a century, providing jobs for thousands of workers. The plant has also been a major contributor to the local tax base, helping to fund schools, roads, and other public services.

In addition to its economic impact, the viscose plant has also had a positive impact on the local community. The plant has been a major supporter of local charities and organizations, and has helped to fund a variety of community projects. The plant has also been a major sponsor of local events, such as the Roanoke Valley Sports Hall of Fame and the Roanoke Symphony Orchestra.

Viscose plant Roanoke VA is a fascinating species with unique properties. It can be transformed into a variety of materials, including rayon and cellophane. Like the exquisite black beauty peony plant , it exhibits an alluring beauty. Its delicate petals unfurl in shades of deep crimson, resembling the finest silk.

Returning to viscose plant Roanoke VA, its versatility and durability make it an essential component in various industries.

Technological Advancements and Innovations

The viscose plant in Roanoke, Virginia, has been at the forefront of technological advancements and innovations in the viscose rayon industry. The plant was one of the first to adopt the continuous spinning process, which significantly increased production efficiency. The plant also installed a state-of-the-art wastewater treatment facility to reduce its environmental impact.

In recent years, the viscose plant has continued to invest in research and development, leading to the development of new and innovative viscose rayon products. These products include high-performance fibers for use in automotive and aerospace applications, and biodegradable fibers for use in disposable products.

The viscose plant in Roanoke, Virginia, was a major producer of rayon, a synthetic fiber made from wood pulp. Rayon was used to make a variety of products, including clothing, bedding, and painted wood plant stands . The viscose plant closed in 1957, but the legacy of its rayon production continues to this day.

Rayon is still used in a variety of products, and the viscose plant in Roanoke, Virginia, played a major role in the development of this important synthetic fiber.

Production Process and Manufacturing Capabilities

The viscose production process involves a series of chemical reactions and mechanical treatments that transform wood pulp into viscose fibers. The key stages include:

- Pulping: Wood chips are treated with chemicals to dissolve the lignin and cellulose, leaving behind a pulp of cellulose fibers.

- Steeping: The pulp is soaked in a solution of sodium hydroxide and carbon disulfide to form sodium cellulose xanthate.

- Ripening: The sodium cellulose xanthate is allowed to age for several hours, during which time it undergoes a series of chemical reactions that weaken the cellulose fibers.

- Dissolving: The ripened sodium cellulose xanthate is dissolved in water to form a viscous solution known as viscose.

- Extrusion: The viscose solution is extruded through spinnerets into a coagulating bath, which contains sulfuric acid and sodium sulfate. The acid causes the cellulose fibers to regenerate and form long, continuous filaments.

- Drawing: The filaments are stretched and drawn to increase their strength and orientation.

- Washing: The filaments are washed to remove any residual chemicals.

- Drying: The filaments are dried to remove excess moisture.

- Finishing: The filaments are treated with various chemicals to improve their properties, such as dyeing, softening, and anti-static treatment.

Machinery and Equipment

The viscose production process requires a variety of specialized machinery and equipment, including:

- Digesters: Large vessels used to dissolve the wood chips in chemicals.

- Steeping tanks: Vessels used to soak the pulp in sodium hydroxide and carbon disulfide.

- Dissolvers: Vessels used to dissolve the ripened sodium cellulose xanthate in water.

- Spinnerets: Nozzles through which the viscose solution is extruded.

- Coagulating baths: Tanks containing sulfuric acid and sodium sulfate, where the cellulose fibers regenerate.

- Drawing machines: Machines used to stretch and draw the filaments.

- Washing machines: Machines used to remove any residual chemicals from the filaments.

- Drying machines: Machines used to remove excess moisture from the filaments.

- Finishing machines: Machines used to treat the filaments with various chemicals to improve their properties.

Quality Control

The viscose production process is subject to strict quality control measures to ensure the consistency and quality of the finished product. These measures include:

- Raw material inspection: The wood chips and chemicals used in the process are inspected to ensure they meet specifications.

- Process monitoring: The temperature, pH, and other process parameters are monitored throughout the production process to ensure they are within the desired ranges.

- Product testing: The finished viscose fibers are tested for strength, elongation, and other properties to ensure they meet industry standards.

- Statistical process control: Statistical techniques are used to monitor the production process and identify any potential problems.

Product Applications and Market Reach

Viscose finds diverse applications across numerous industries, owing to its versatility and desirable properties. It is widely used in the production of textiles, nonwovens, and specialty materials.

The unique characteristics of viscose, such as its softness, breathability, and moisture absorption, make it suitable for a wide range of products, including clothing, home furnishings, and medical textiles.

Textiles

- Apparel: Viscose is a popular choice for clothing due to its drape, comfort, and ability to blend with other fibers, such as cotton and polyester.

- Home Furnishings: Viscose is used in curtains, upholstery, and carpets, providing a luxurious and elegant touch to interiors.

Nonwovens

- Hygiene Products: Viscose is found in disposable wipes, diapers, and sanitary pads due to its softness and absorbency.

- Medical Textiles: Viscose is used in surgical gowns, bandages, and dressings, offering breathability and comfort to patients.

Specialty Materials

- Rayon: Viscose can be processed into rayon, a lustrous fiber used in clothing, bedding, and other applications.

- Cellophane: Viscose is used to produce cellophane, a transparent film used for packaging and wrapping.

The Roanoke viscose plant plays a significant role in meeting the global demand for viscose products. Its strategic location and efficient distribution channels ensure timely delivery to customers worldwide.